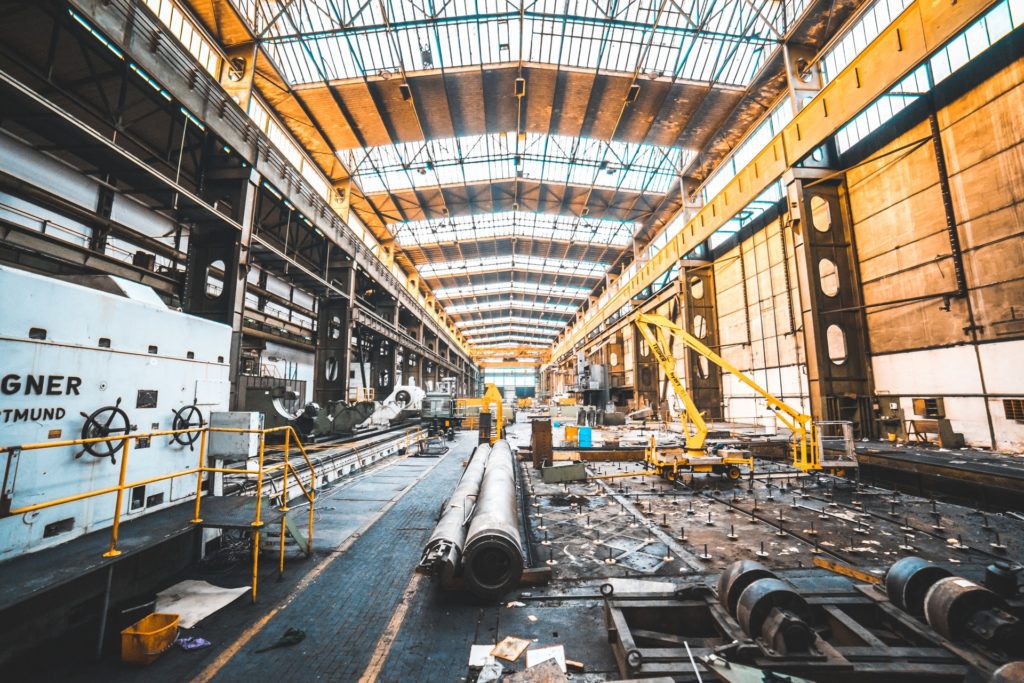

Unlike in past decades when maintenance was somewhat hit-and-miss, the wide availability of advanced solutions today means that equipment owners can progress from reactive to more proactive maintenance programs backed by real-time analytics. You may have heard the terms “Predictive Maintenance,” or “PdM” and even “CMMS” thrown around in maintenance or engineering circles and you’re wondering if these technologies can take your maintenance systems to the next level. Well, in this post, we hope to introduce you to the essentials of these technologies, show you how they work together, and then discuss some of the great benefits that these tools…